Parts List:

From Get FPV:

1x 40 Xilo ESC: $8.99 Purchase Here

1x 2400kv Emax Eco II 206 Brushless Motor: $15.99 Purchase Here

From Palm Beach Bots:

2x Repeat Robotics Brushed Planetary Motor: $36.00 Purchase Here

1x Fingertech Foam Wheels 0.7"5"x 2.00" (2x): $3.37 Purchase Here

From Aliexpress:

1x Dual Brushed ESC: $4.22 Purchase Here

From Amazon:

1x 300 mah 3s LiPo Battery (2x): $24.59 Purchase Here

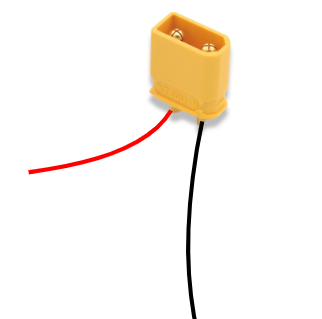

1x XT30 Electrical Connector: $8.99 Purchase Here

1x M3 Screw Assortment: $10.99 Purchase Here

1x Aluminum M3 Standoff (10x):$9.99 Purchase Here

From Betz Botz:

1x Betz Botz Plastic Wheel Hubs (2x): $9.50 Purchase Here

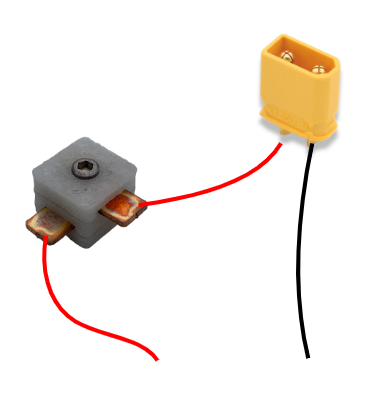

1x Betz Botz Power Switch: $5.00 Purchase Here

Purchased Parts Estimated Cost: $137.63

Manufactured Parts Estimated Cost: $58.50

Total Estimated Cost: $196.13

Optional Components (Recommended for new builders)

1x B3 Pro Compact Balance Charger 2s/3s: $9.99 Purchase Here

1x LiPO battery bag: $5.49 Purchase Here

1x Flysky FS-i6 2.4 GHz 6 Channel Transmitter: $52.99 Purchase Here

1x Weapon safety clamp: $14.18 Purchase Here

1x Latex paint bottle (For wheel traction): $12.99 Purchase Here

1x Blue Loctite bottle: $7.87 Purchase Here

1x Spare 18AWG wire: $13.98 Purchase Here

CAD, Laser cut, and 3D Print Files:

Build Instructions

Required Tools

Hex key set

Pliers

Wire Cutter/Stripper

Soldering Iron & electrical solder

Small Phillips Head Screwdriver

Electrical tape

Manufacturing Parts

The top plate, bottom plate, and weapon blade will need to be laser cut by a service such as SendCutSend. It is recommended that .080" thick 6061 Aluminum be used for the top plate, and .125" thick 6061 Aluminum is used for the bottom plate. The weapon blade should be made from .119" thick AR500 Steel.

The blade clamp, motor keys, and divider will need to be 3D printed. This can be done from a variety of materials, but TPU is recommended. Betz Botz, the designer of this kit, offers 3D printing services if needed.

Mechanical Assembly

Step 1:

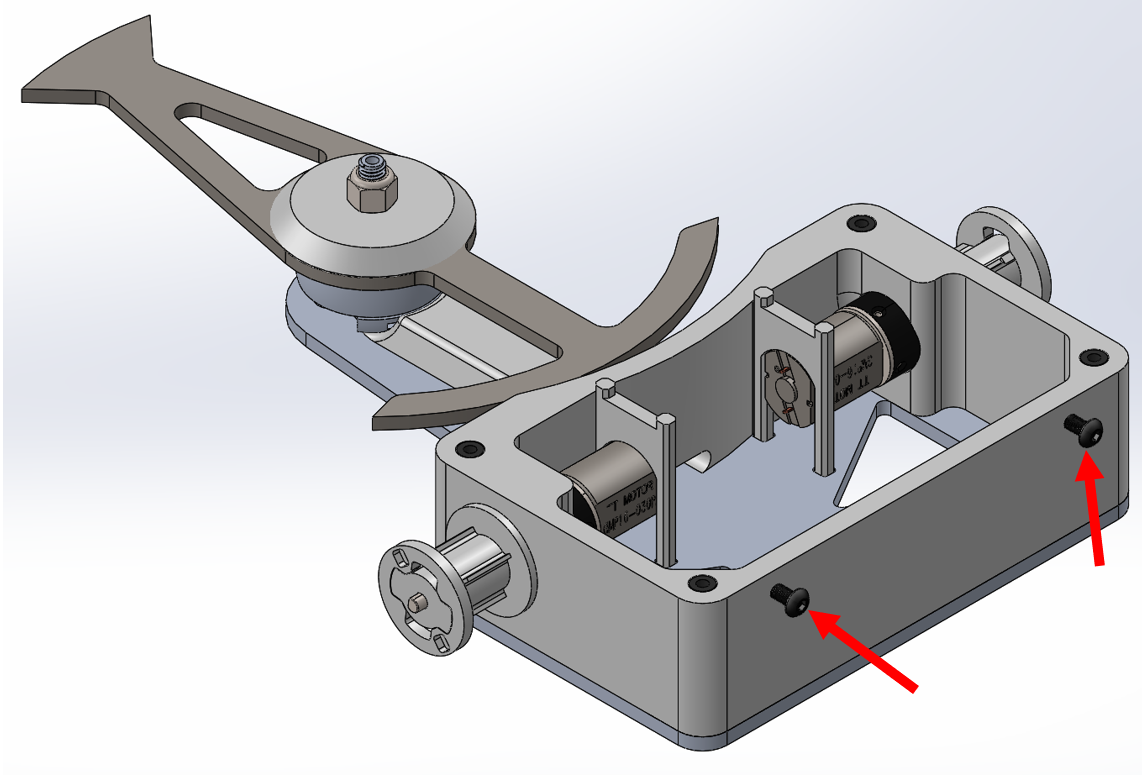

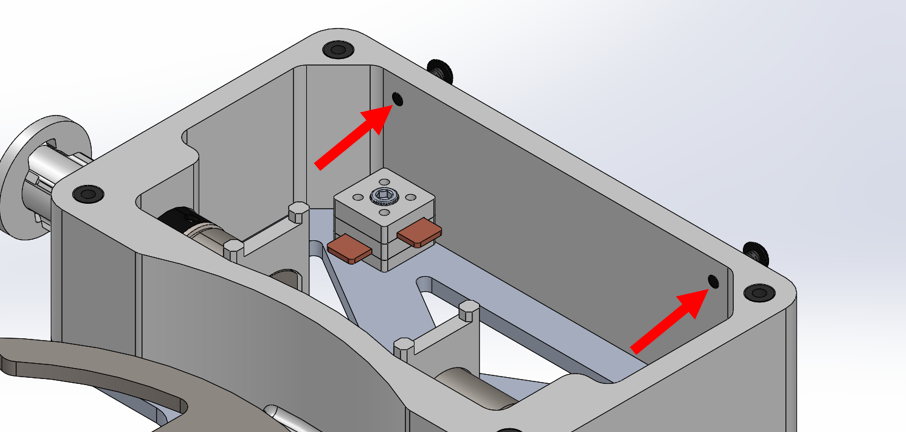

Assemble the four standoffs to the bottom plate using M3 x 10 mm screws. Hold the standoffs with pliers while tightening the screws

Step 2:

Place the divider on the bottom plate, holding it in place with the standoffs

Step 3:

Slide both Repeat Robotics drive motors into place on the divider. Ensure the bushing is flush with the outside face of the robot

Step 4:

Slide the wheel hubs over the motor shafts, then tighten the set screw until snug. When properly tightened, the hubs will not move on the shaft when tugged. Overtightening will lead to thread stripping in the hub

Step 5:

Insert the motor keys into the bottom plate to keep the drive motors in place

Step 6:

Attach the power switch to the bottom plate using the included hardware. Hold the switch in place while tightening screws

Step 7:

Assemble the brushless weapon motor to the bottom plate using 4x M3 x 6mm screws. Ensure the motor wires are threaded through the channel on the divider

Step 8:

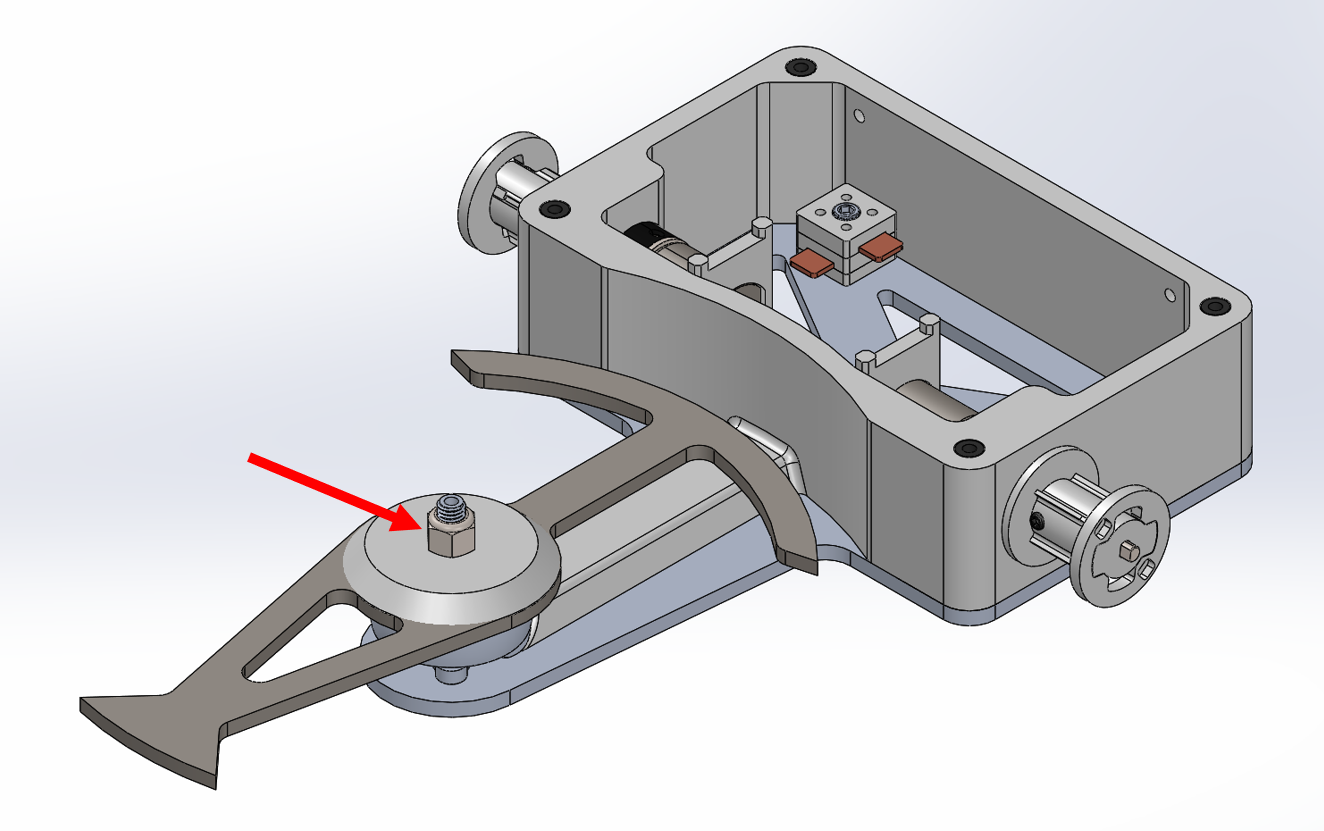

Place the weapon blade over the brushless motor, slotting it into the vents. Then place the blade clamp over the blade

Step 9:

Tighten the locknut (included with the brushless motor) using a pair of pliers or 8 mm socket. Ensure it is snug against the blade clamp

Step 10:

Screw 2x M3 x 10 mm screws into the back of the divider. Ensure they are flush with the inside wall of the divider. These fasteners are there to prevent the robot from getting stuck on its back during combat, or "doing the thing" as its commonly known in roboteer speak

Step 11:

Press the foam wheels onto the wheel hubs, then twist on the lock washers over the wheels using the provided twist key

Electrical Assembly

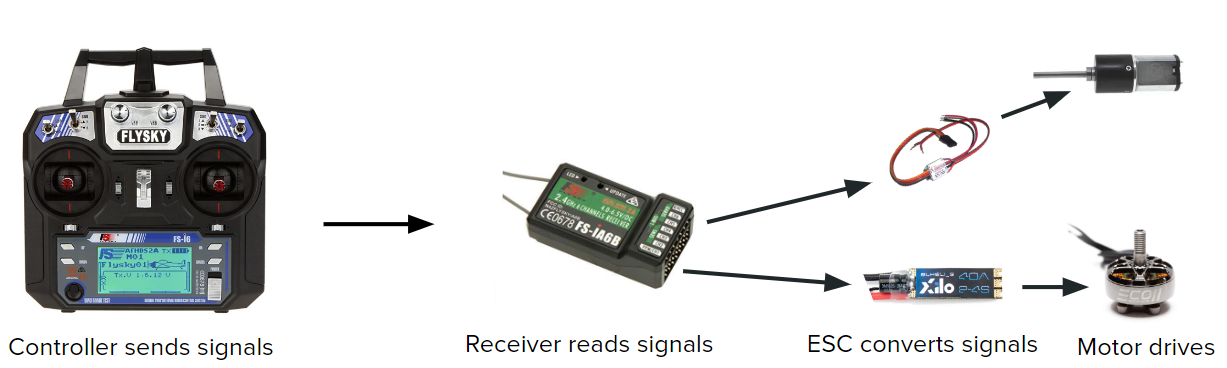

Combat robotics wiring has a learning curve. Not only does it require sharp soldering skills, but understanding the electronics takes time too. Thankfully, the same basic principals apply to all robots.

Hobby R/C systems used in combat robotics share components and concepts with R/C cars, boats, planes, helicopters, and drones. A controller is used to transmit a radio signal to a receiver. This receiver then sends the signal to the electronic speed controllers (ESCs). The ESCs then break up the signal into pulses which the motors can understand.

Assembling this wiring harness requires basic soldering skills. Endbots has a great tutorial on soldering, which can be found here

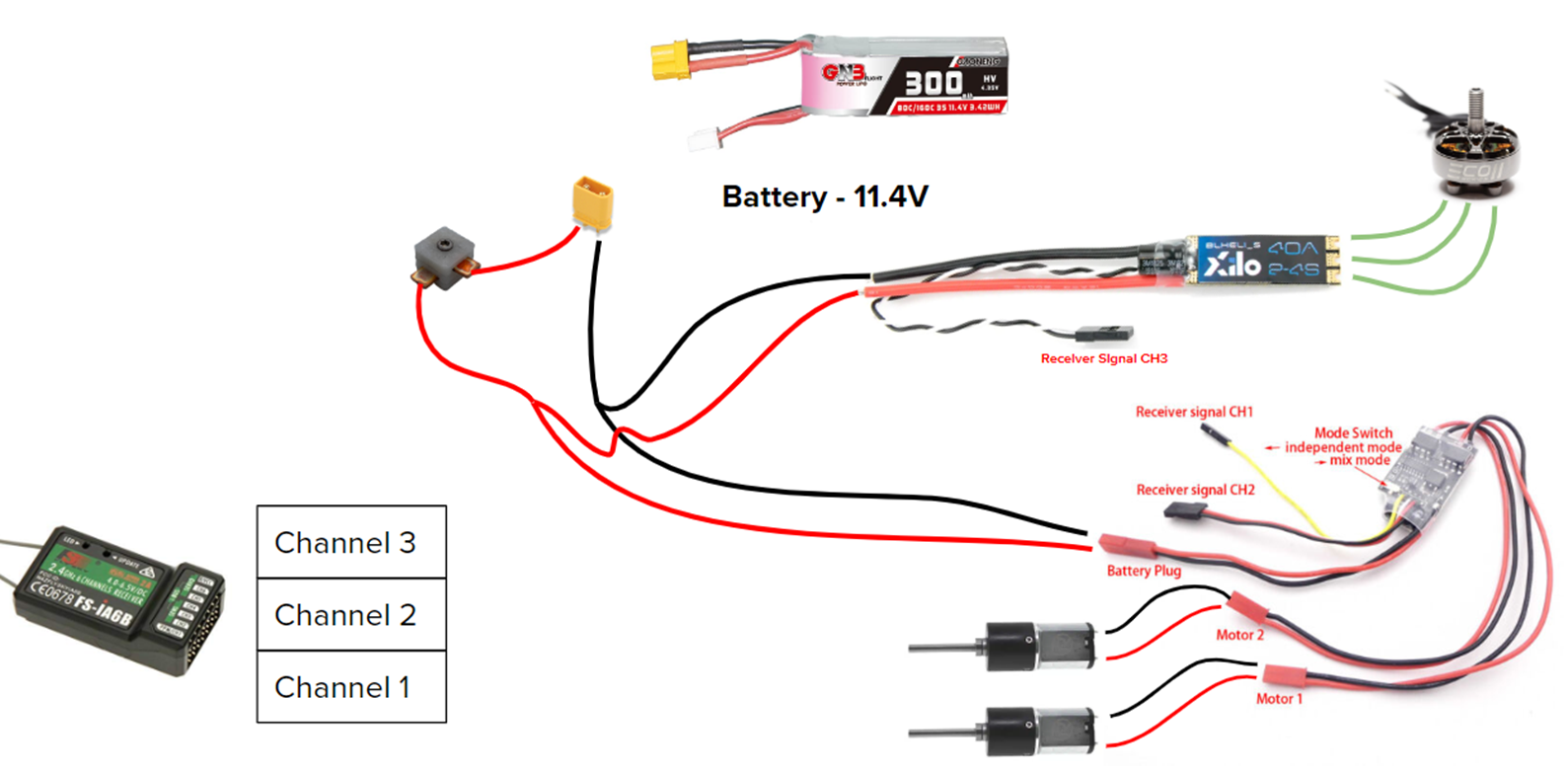

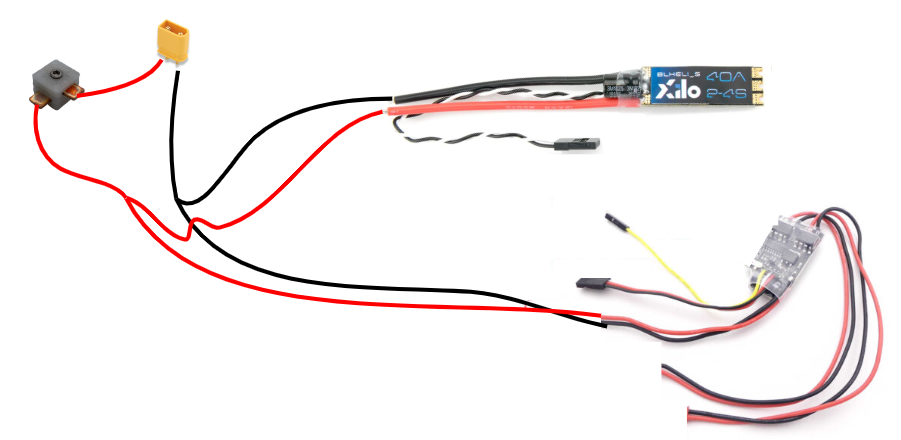

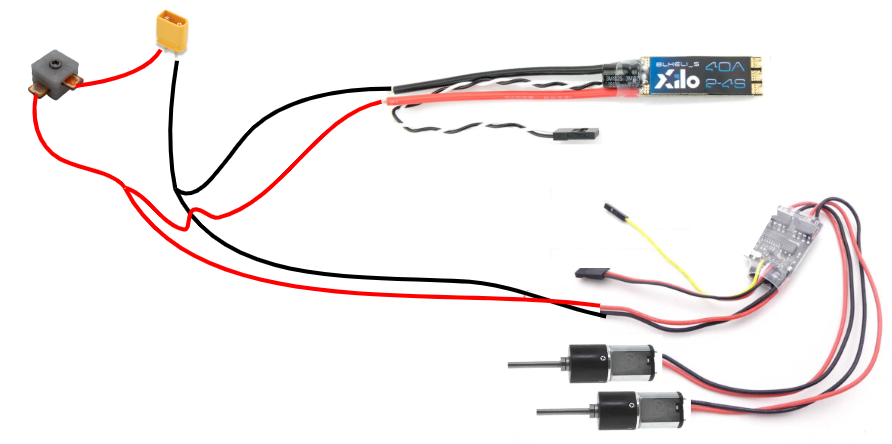

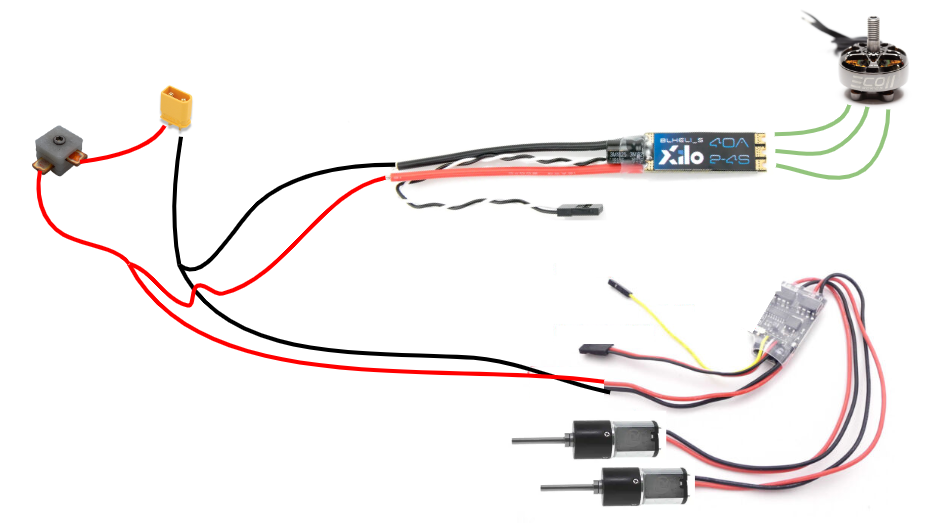

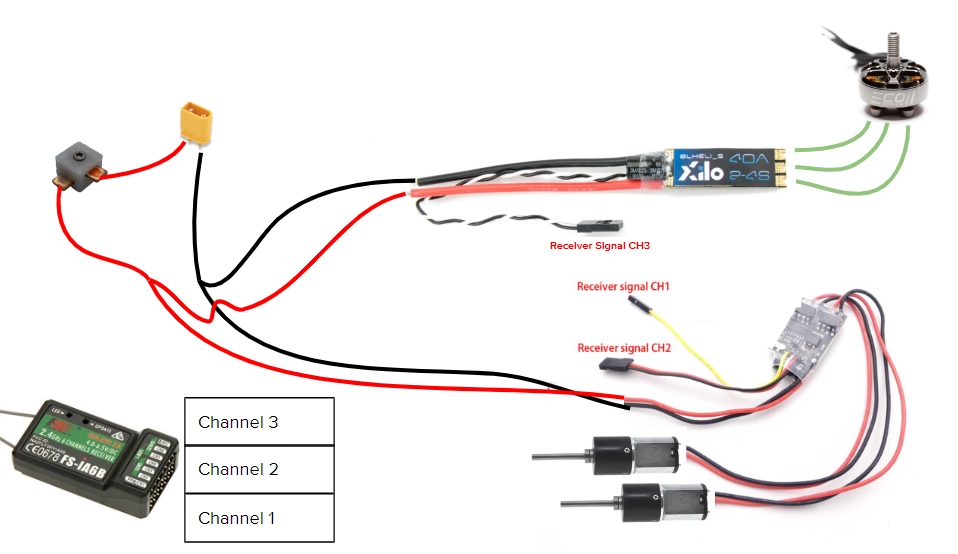

Wiring Diagram:

Step 1:

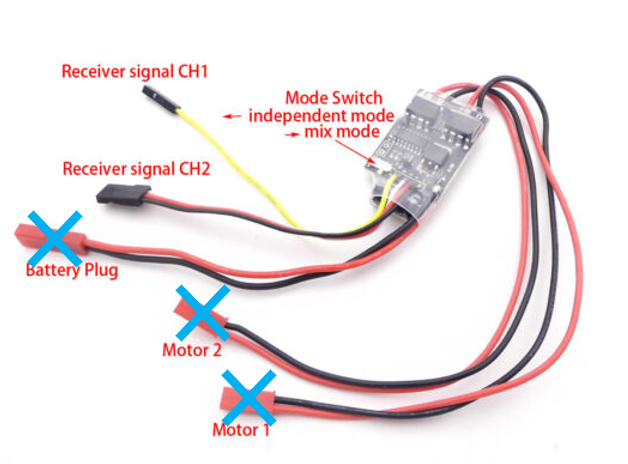

Remove all three JST connectors from the Dual Brushless ESC by cutting their wires right at the base of the connector. The ESC will be soldered directly to the motors, so these connectors are not needed

Once the JST connectors are removed, cut these wires to length so they will be able to reach the motors without much excess. Save the cut wires, they will be used elsewhere in the harness

Step 2:

Solder all of the excess black wire to the negative side of a female XT30 connector. Solder half of the excess red wire to the positive side of the XT30 connector

Step 3:

Solder the red wire on the XT30 connector to the power switch. proceed to solder the remaining excess red wire to the other terminal on the power switch

Step 4:

Wire the solder the red wire on the battery end of both the dual ESC and the brushless ESC to the red wire on the switch. Wire the black wire on both ESCs to the black wire on the XT30 connector.

Once these joints are soldered, cover them with either heat shrink or electrical tape

Step 5:

Solder the Repeat Robotics drive motors to the dual ESC

Step 6:

Solder the three brushless weapon motor wires to the pads of the brushless ESC. It does not matter which wire is connected to which pad

Step 7:

Plug the signal wires from the dual ESC into channels 1 and 2 of the receiver. Plug the signal wire from the brushless ESC into channel 3 of the receiver

Step 8:

Attach the battery to the XT30 connector, and assemble the wiring harness into the robot

Step 9:

Attach the top plate of the robot using 4x M3 x 6mm screws

Testing & Troubleshooting

Once the robot is assembled and wired, test it to ensure all systems are running as expected. While testing, it is critical to have the weapon blade removed to ensure safety. The robot should also be set on blocks or have the wheels removed so it doesn't drive anywhere unexpectedly if something is set up wrong. Always use more caution than you believe to be necessary when testing.

Once initial tests have been run to ensure the electronics are operating as expected, additional testing can be done with the weapon in a test box made from plywood and polycarbonate. Instructions on how to make a simple test box can be found here

Getting all of the motors spinning in the correct direction can take some trial and error. Here are some tips to work through any issues:

While testing, if either of the drive motors are running backwards, they can be fixed by swapping the motor terminals the red and black wires are connected to.

If the robot is turning left when it should be turning right, swap the signal wires in channels 1 and 2 of the the receiver.

A switch on the dual ESC can also be switched to change to mixing mode.

If it is desired to have the weapon spinning the opposite direction, swap any two of the three wires connected to the brushless ESC pads.

Conclusion

Once troubleshooting is complete, the robot is ready to fight! Check out the websites RobotCombatEvents.com and BuildersDB.com to find an event near you

WARNING!

Combat robots are not toys and should always be treated with respect.

Always use a weapon lock and test in an adequate test box.

Design by Joseph Betz of Betz Botz